Viglacera and HESS AAC SYSTEMS (Germany) signed a contract to provide consulting services and technical equipment for the science and technology project on production of concrete brick

On September 15, 2017, Viglacera signed a contract with Hess AAC SYSTEMS (Germany) to provide consulting services and high technology equipment for the science and technology project "Research Manufacture of equipment lines and technology of production of concrete brick with the capacity of 200,000 m3/year". This science and technology project is owned by Viglacera, Funded by state budget and owner's capital, in cooperation with partner HESS AAC SYSTEMS from Germany is one of the world's leading companies in research, consultancy and technology transfer, supply Supply high-tech equipment in the field of air-pressure concrete production. rescue, consult and transfer technology, provide high-tech equipment in the field of manufacturing air-pressure concrete (AAC); research and consultancy on the use of various materials for the production of gas concrete and non-baked products. By the year 2017, the contractor has supplied equipment, synchronous production lines and technology transfer to more than 87 customers in Europe, Turkey, Mongolia, Iran, India, Philippines ... Attending the signing ceremony, there are leaders from the Departments, specialized institutes under the Ministry of Construction, the Ministry of Science and Technology and the Ministry of Industry and Trade and dosmetic and international associations.

Signing contract for providing consulting services and technical equipment for the science and technology technology production of concrete brick with a capacity of 200,000 m3/year between Viglacera and Hess AAC Systems (Germany).

At the same time, Viglacera and HESS AAC SYSTEMS work together to focus on the use of raw materials from the waste industry such as fly ash, ash. This issue is being considered because the electricity industry is under pressure due to the lack of treatment options. (According to the information presented at the conference "Coal-fired Thermal Power Development and Environmental Protection Solutions" held by National Assembly Science, Technology and Environment Committee on 29/8/2017, present There are now approximately 20 active thermal power plants, with a capacity of nearly 14,500 MW, generating about 15.8 million tons of ash or gypsum a year, and using a total of 700 ha of dumping sites. How to handle this ash is not harmful to the environment. Ashes discharged without treatment will be filled with reservoirs, causing environmental pollution and the plant will not be able to operate).

Mr Nguyen Anh Tuan, General Director of Viglacera and Mr René Klopper - Managing Director of Hess AAC Systems BV signed a memorandum of understanding to expand about 3 to 5 brick-and-mortar brick factories from raw materials. waste electrical industry.

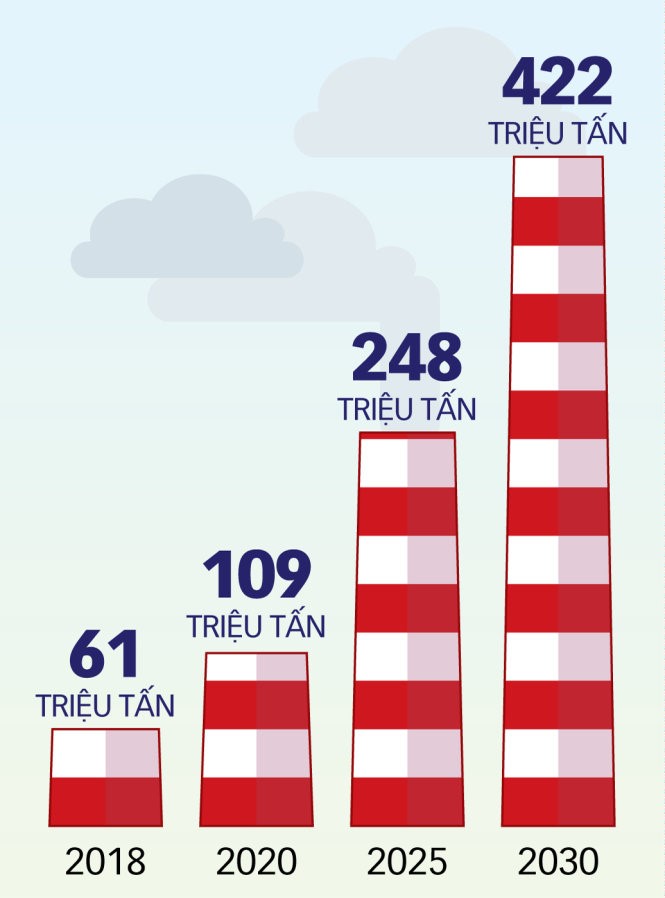

In addition to the scarcity of land resources, bricks that use land resources will replaced by bricks produced from other sustainable and friendly materials such as concrete brick. At the same time, Viglacera and HESS AAC SYSTEMS have signed a cooperation agreement to expand 3 to 5 factories with high technology mainly using abundant raw materials from the electrical industry. According to the forecast of Institute of Construction Materials , the electricity sector's waste will be surplus to 248 million tons by 2025. This cooperation will deal with waste for the power sector as well as the environmental protection

Mr. René Klopper, CEO of Hess AAC Systems B.V makes a speech at the signing ceremony

Dr. Le Trung Thanh – Director general of Department of Science, Technology and Environment - Ministry of Construction highly appreciated Viglacera's responsibility and efforts in environmental protection.

Amount of Ash from the thermal power plant is forecast to emit

Source: Institute of Building Materials. Graphic: T.Đ

The science and technology project "Research and manufacture of equipment lines and technology of production of concrete brick with a capacity of 200,000 m3/year" will be able to consume between 30,000 and 60,000 tons Waste ash slag heating every year. This project shall be implemented by Viglacera Concrete Factory of Viglacera Concrete Joint Stock Company, Yen Phong Industrial Zone, Yen Phong District, Bac Ninh. Currently, the capacity of the production line is 100,000 m3 / year, operating from 2010 with the product quality reaching TCVN 7959: 2011. After completing the project in April 2018, Viglacera is expected to increase its production capacity to 200,000 m3 per year with the most modern equipment and technology from HESS AAC SYSTEMS (Germany).